Undercarriage Parts And Bulldozer Assembly For Js200 Excavator Zax 85 Idler

Product Description

The idler (guide wheel) is used to guide the track to rotate correctly and prevent deviation and derailment. The idler (guide wheel) of some hydraulic excavators also functions as a roller, which can increase the contact area between the crawler and the ground and reduce the specific ground pressure. Most of the wheel surfaces of the idler are smooth, with a shoulder ring in the middle as the guide, and the ring surfaces on both sides can support the chain and the roller. The shoulder ring in the middle of the idler (guide wheel) should have sufficient height and the slope on both sides should be small. The smaller the distance between the guide wheel and the nearest roller, the better the guiding performance.

Zax 85 idler adopts the box structure cast by resin sand process. The appearance quality of the wheel body has reasonable mechanical structure performance. The matrix is normalized to obtain good impact resistance, and the medium frequency induction quenching heat treatment of the track surface. Surface hardness To hrc48-54, the depth is not less than 6mm, with wear resistance in harsh conditions

ILDER: forged material (50MNb)

Depth: 6mm (Shaft1.5-2mm) Hardness: HRC48-54

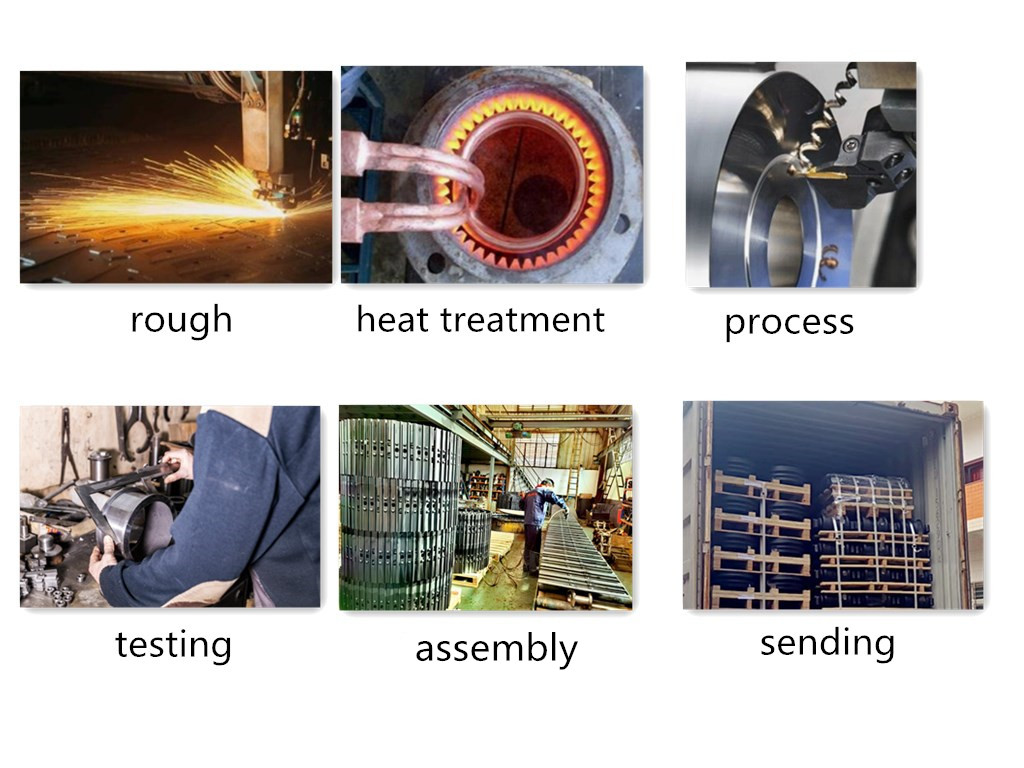

IDLER body: forging - turning - quenching - fine turning - pressure bushing - welding slag shovel (cleaning the surface of the machine body)

| Material | 50Mnb |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC52 , Depth6mm |

| Colors | Black or Yellow |

| Warranty Time | 1440 Working Hours |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 25-100/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

| type | bulldozer undercarriage parts |

| Moving Type: | Crawler bulldozer |

| After-sales Service Provided: | Video technical support, Online support |

We all use the best 50mnb steel as raw materials, and use differential quenching to increase the hardness of the IDLER , increase the wear resistance of the IDLER , and delay the wear of the IDLER body.

Co-branding

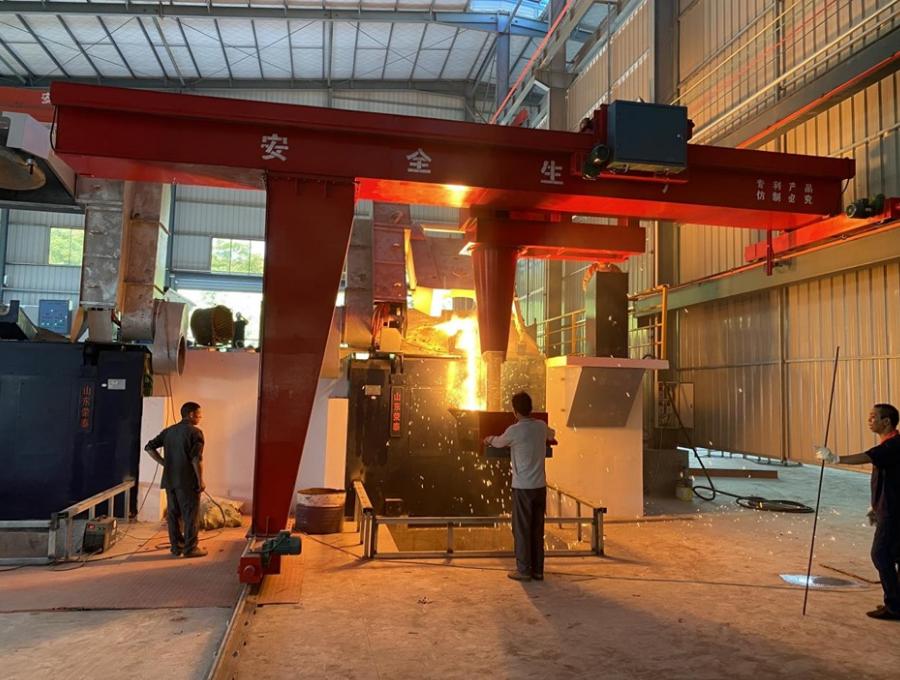

We have our own processing plant and foundry to show you the best quality

Packing and shipping

More Excavator idler for your review:

Model / Part number / SIZE / Weight

1. D3B D3C / 6Y2047 / 25T25H5 / 19.5KG

2. D4D / 7K2514 4V4107 / 29T / 39KG

3. D5 / 5S0836 / 27T27H9 / 46.8KG

4. D6C D6D / 6P9102 / 25T20H5/55.5KG

5. D6H / 7G7212 / 25T25H5 / 57.5KG

6. D7H / 9P1898 /25T25H5 / 74KG

7. E110B E311B E312B E314C / 4I7472 / 21T15H / 39.3KG

8. E180 MS180-8 / 095-7412 / 23T22H / 53KG

9. E200B / 096-4327 / 21T14H / 47.8KG

10. E318B E320B E320C / 8E9805 / 38.5KG

11 .E320S E325 E325B E325N / 6Y4898 / 21T18H /53.5KG

12. E330 E330B / 6Y5685 / 23T16H / 94.5KG

13. PC60-5 / 201-27-41110 /23T12H / 23KG

14. PC60-6 / 21W-27-11110 / 21T12H / 22.3KG

15. PC100-3 PC120-3 / 203-27-411111 / 25T15H / 44KG

16. PC100-5 PC120-5 / 203-27-51310 / 21T15H / 33.8KG

17. PC200-3 / 205-27-71281 / 21T20H / 39KG

18. PC200-5 PC200-6 PC200-7 PC220-5 PC220-6 PC220-7 / 20Y-27-11581 / 21T20H / 39KG

19. PC300-6 PC300-7 PC350-6 / 207-27-61210 / 21T20H / 67KG

20. PC400-3 PC400-5 / 208-27-61210/ 23T26H / 66KG

21. EX100 EX120 ZAX110 ZAX120 / 1010325 / 21T16H / 33KG

22. EX200-2 EX220 / 1010203 / 21T16H / 44KG

23. EX200-3 / EX200-5 / 1018740 / 21T16H / 46.4KG

24. EX300-5 EX330-5 ZAX270 ZAX350 / 1022168 / 21T20H / 89KG

25. SK07-2 SK07-2 / 2404N246 / 23T16H / 56KG

26. SK07-N2 / 907-2 / 2404N251 / 25T20H / 56KG

27. SK100 SK120 / 2404N416 / 21T15H / 36.5KG

28. SK200-3 SK200-5 / 2404N414 /21T22H / 47KG

29. SH200 HD820 / KRA1109 KRA1665 / 21T22H / 52KG

30 .DH320 / 2108-1024 / 23T24H / 60.8KG

ABOUT US

Fujian Jinjia Machinery Co.,Ltd. is developing from Quanzhou Hongda Machinery Co.,Ltd. The company has dedicated to the manufacturing of crawler undercarriage parts since 1990, which has been more than 30years so far. Now we have established our own casting, forging and machining production centers.

JINJIA Machinery has always been insisting on the operation policy of “Customer first, Quality first” . Our mission is to make customer satisfaction. Just because of this, these years the company has obtained high reputations and solid foundation in the machinery industry. Today our production scales have been constantly expanding, with a wide range of product categories. Our products have been popular in domestic markets as well as the international markets such as Europe, America, South East of Asia, Middle East, etc. We have established good business relationships with famous companies around the world. Welcome to visit our factory for further more technological communications!

Exhibitions over the years

FAQ

Q: Are you trading company or manufacturer ?

A: We are an industry and trade integration business,our factory located in Quanzhou, and our sales

departments are in Jingjiang.

Q: How long is your delivery time?

A: Generally it is 7 days if the goods are in stock. or it is 20-30 days if not in stock. If it is customized,

it will be confirmed according to order.

Q: What about Quality Control?

A:We have excellent tester, check every piece to ensure the quality is good, and check the quantity is

correct before the shipment.