Track Shoes For Crawler Track

Product Description

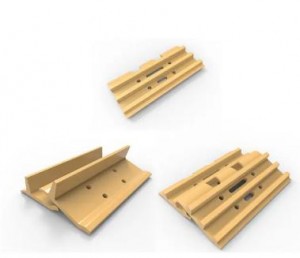

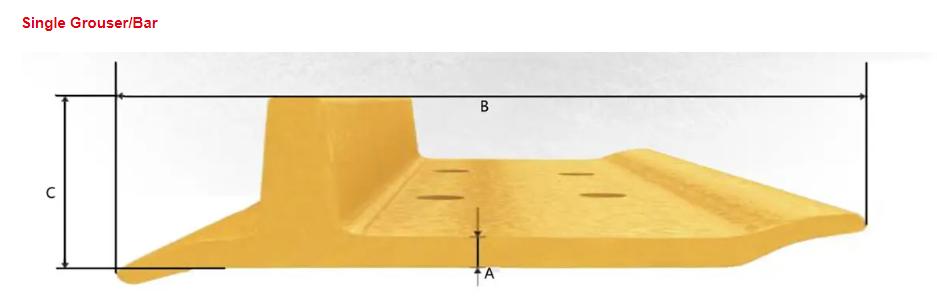

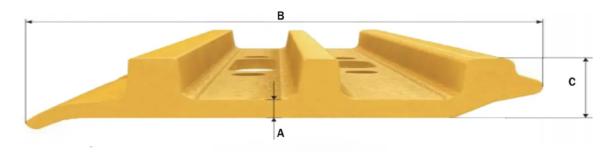

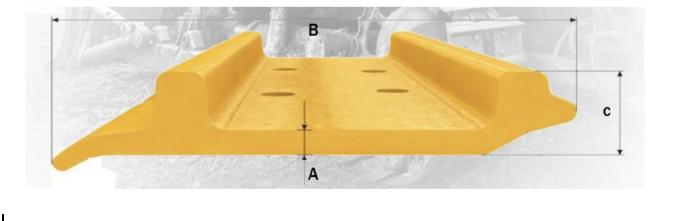

Commonly used track shoes are divided into three types according to the grounding shape, including single rib, three rib and flat bottom, and some also use triangular track shoes. Single-reinforced track shoes are mainly used for bulldozers and tractors, because the track shoes are required to have high traction capacity when such machinery works. However, it is rarely used on excavators. This kind of track shoe is only used when a drill frame is installed on the excavator or when a large horizontal thrust is required. High traction force is required when turning by the sub, so the higher tread bars (ie stabs) will squeeze away the soil (or ground) between the tread bars, thus affecting the mobility of the excavator.

Track shoes: forged material (50MNb)

Depth: 3mm (Shaft1.5-2mm) Hardness: HRC55-60

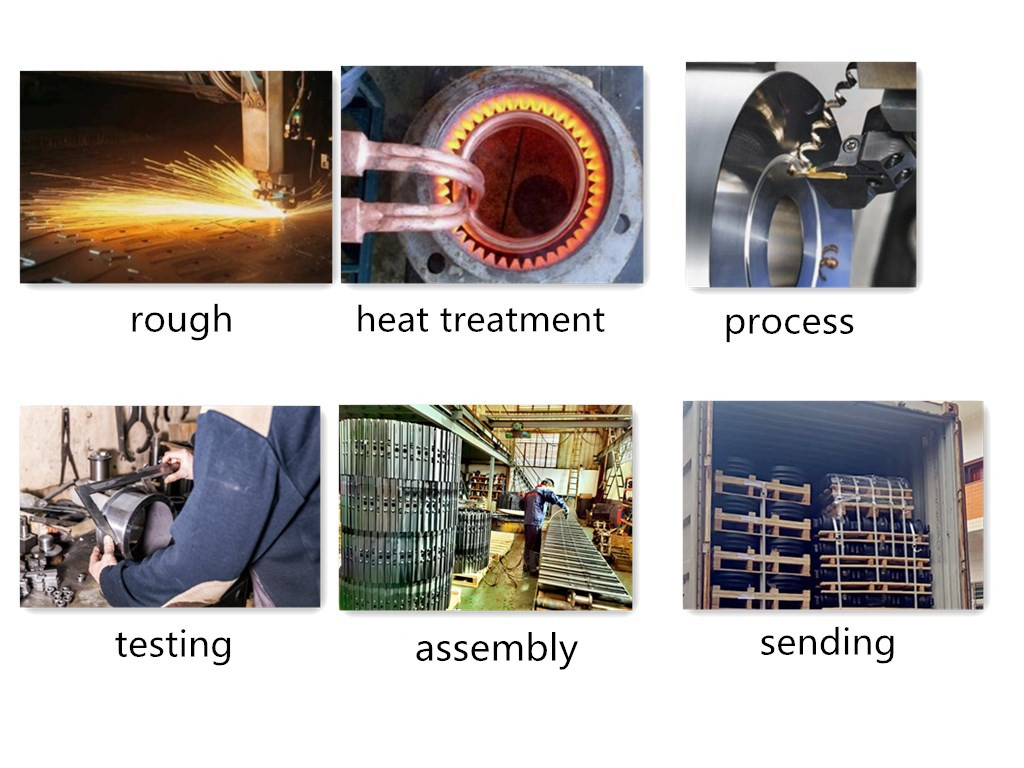

Roller body: forging - turning - quenching - fine turning - pressure bushing - welding slag shovel (cleaning the surface of the machine body)

Shaft Forging Turning Operation Drill Tapping Quenching and Tempering Grinding

Track shoe Parts: Test Paint Check Storage

| Material | 50Mnb | |

| Finish | Smooth | |

| Technique | Casting/Forging | |

| Surface Hardness | HRC56 , Depth10-12mm | |

| Colors | Black or Yellow | |

| Warranty Time | 1440 Working Hours | |

| Certification | IS09001-9001 | |

| MOQ | 2 Pieces | |

| FOB Price | FOB Xiamen US$ 25-100/Piece | |

| Delivery Time | Within 30 days after contract established | |

| Payment Term | T/T,L/C,WESTERN UNION | |

| OEM/ODM | Acceptable | |

| type | bulldozer undercarriage parts

|

|

| Moving Type: | Crawler bulldozer | |

| After-sales Service Provided: | Video technical support, Online support |

We all use the best 50mnb steel as raw materials, and use differential quenching to increase the hardness of the track shoe , increase the wear resistance of the track shoe , and delay the wear of the track shoe body.

Our main products are track rollers, top rollers, sprockets, idlers, track links for various types of excavators and bulldozers, as well as pins, bushings, high-strength bolts and nuts, buckets, cylinders, pistons , and many more

If you need a lot of new products, if you are interested in our company, we can also develop new products for you. If you do not find the type you want on our homepage, please give us the specific information of the type you want, then send us an email, we will deal with it as soon as possible and will try our best to help you.

Application

excavator

Bulldozer

Packing and shipping

ABOUT US

Fujian Jinjia Machinery Co.,Ltd. is developing from Quanzhou Hongda Machinery Co.,Ltd. The company has dedicated to the manufacturing of crawler undercarriage parts since 1990, which has been more than 30years so far. Now we have established our own casting, forging and machining production centers.

JINJIA Machinery has always been insisting on the operation policy of “Customer first, Quality first” . Our mission is to make customer satisfaction. Just because of this, these years the company has obtained high reputations and solid foundation in the machinery industry. Today our production scales have been constantly expanding, with a wide range of product categories. Our products have been popular in domestic markets as well as the international markets such as Europe, America, South East of Asia, Middle East, etc. We have established good business relationships with famous companies around the world. Welcome to visit our factory for further more technological communications!

Exhibitions over the years

FAQ

Q: Product usage?

A: If any problem about usage, I will solve at first time.

Q:What about Quality Control?

A:We have a perfect QC system for the perfect products. A team who will detect the product quality and specification piece carefully, monitoring every production process until packing is complete, to ensure product safety into container.