OEM Quality D7G bulldozer track roller excavator bottom roller and lower roller

Product Description

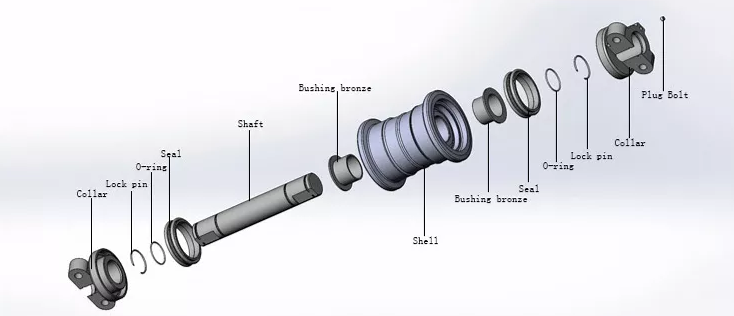

The design of double flange rollers is suitable for small excavators and heavy excavators and bulldozers of 0.2-120 tons. Or special versions of rollers for forestry and agricultural applications, both can be used

The double-code seal design extends the service life and is a cost-effective choice.

Our double flange rollers will undergo a series of quenching treatments to ensure that the surface hardness reaches hrc=50. The wheel shells are mainly made of hot forging treatment to obtain excellent internal material fiber flow distribution structure.

Differential quenching has the effect of anti-cracking and prolongs the service life

Top Roller :forging material(50MN) Cover material (QT450)Shaft (45#)

Degree of depth :3mm(Shaft1.5-2mm)Hardness:HRC55-60

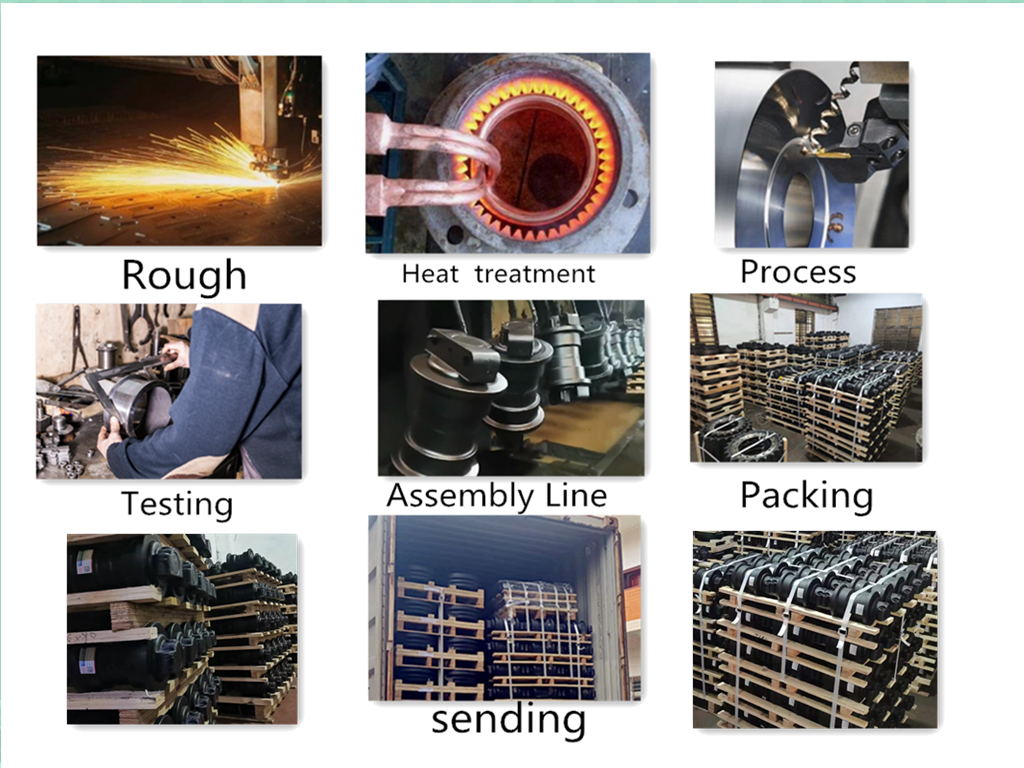

Roller body: Forging--Turning operation--Quenching--Fine Turing operation --pressure bushing--- welding slag shovel (clean up the body surface)

Shaft forging turning operation drill tapping tapping temper quenching mill right

Handed screw

End cover :forging/casting/steel rod-rough and fine turning operation drill tapping

All parts ready to: assembly-Pressure Test Filling Oil Spray Paint Checking Storage

| Material | 50Mn |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC55-60 , Depth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 1440 Working Hours |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 25-100/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

The materials avaliable for Track roller are 40Mn2、40MnB、50Mn,depending on working conditions.The rollers are normalized with precision forging before overall heat treatment to achieve surface hardness or HRC52-6 and the depth of hardened layer reaches more than 7-10mm(HRC45).This ensures higher durability with high impact resistance and surface wear resistance on the contact surface of the roller.High quality floating saels and lubrcating system are usde to adapt to different climate and temperature The track and carrier rollers is able to work under severe working conditions or climate ranging from -45℃~120℃,keeping the components free from miantenance.

Our Track Roller is welded before precision machining in vertical CNC turning lathe and hence,there is no concentricity errors.The process gives unparalleled quality quality advantage over that of precision machning before welding.Therefore,the operation of roller is be guaranteed against occurrence of rapid wearing problems,which significantly improves service life of the products.

Packaging & Shipping

Fujian Jinjia Machinery Co., Ltd. is an excellent supplier of excavator parts and bulldozer parts in China. Our main products are the chassis parts of excavators and bulldozers, such as rollers, idlers, etc.

More than 50 years of experience in the sales of heavy machinery spare parts, important customers are mainly located in Southeast Asia, the Middle East, South America and some Eastern Europe We have established good business relationships with famous companies around the world. Welcome to visit our factory for further more technological communications!

FAQ

How long is the after-sale time?

Our warranty time about 1440 Working Hours

Can I customize my favorite logo on the product?

It is no problem to customize the logo on the product, as long as you meet our minimum order quantity, you can customize the logo