LS118 Custom Track Roller Parts Carriage 60T For Link-Belt

Product Description

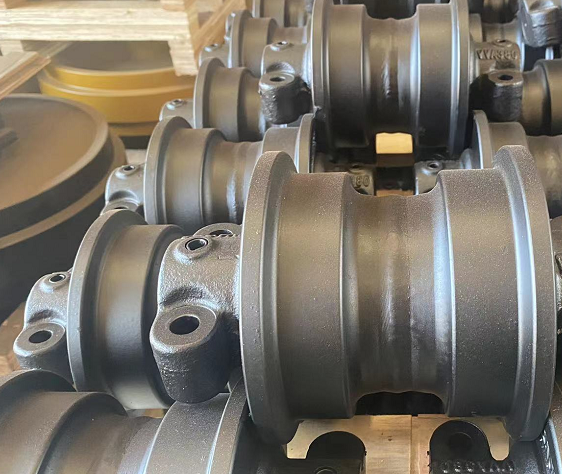

The track rollers produced by our company are suitable for small excavators and heavy excavators and bulldozers from 0.2-120 tons. There are single flange and double flange models, and they are suitable for special road milling machines, pavers, forestry and agricultural applications.Version Roller.

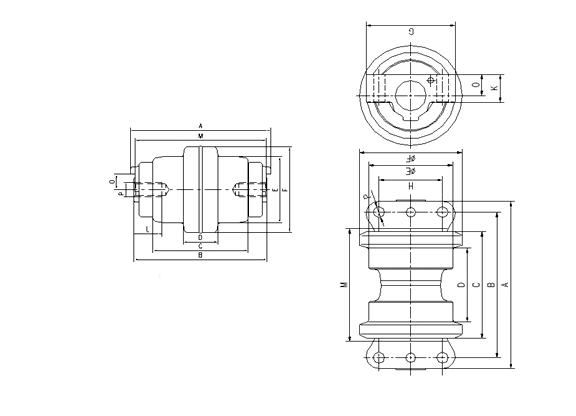

The roller is a part that requires high wear resistance, so we not only need to carry out quenching and tempering treatment to make its internal structure uniform and fine. make the hardness reaches HRC50. And if the wear resistance is not high, pass-through quenching treatment will also be carried out to improve the wear resistance of the rollers.

Top Roller :forging material(50MN) Cover material (QT450)Shaft (45#)

Degree of depth :3mm(Shaft1.5-2mm)Hardness:HRC55-60

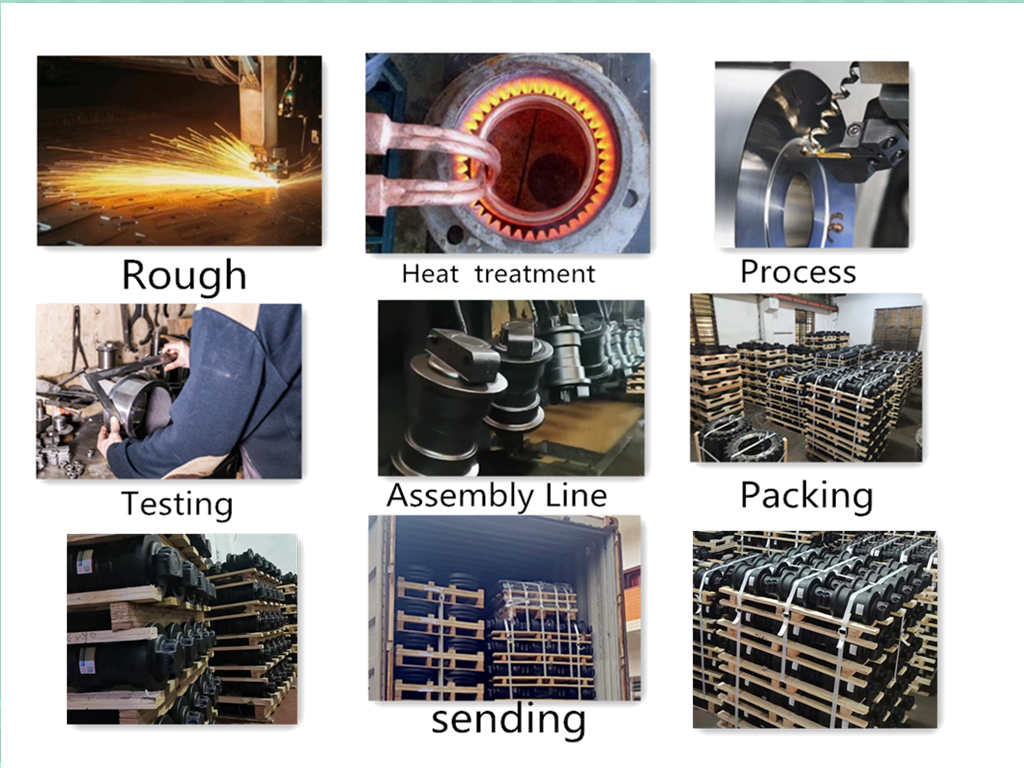

Roller body: Forging--Turning operation--Quenching--Fine Turing operation --pressure bushing--- welding slag shovel (clean up the body surface)

Shaft forging turning operation drill tapping tapping temper quenching mill right

Handed screw

We all use the best 50mn steel as raw materials, and use differential quenching to increase the hardness of the workpiece, increase the wear resistance of the rollers, and delay the wear of the wheel body.

End cover :forging/casting/steel rod-rough and fine turning operation drill tapping

All parts ready to: assembly-Pressure Test Filling Oil Spray Paint Checking Storage

| Material | 50Mn |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC55-60 , Depth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 1440 Working Hours |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 25-100/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

We use the best double cone sealing method, choose the best sealing ring and gear oil, and correct the roundness of the product shaft sleeve, in order to reduce the risk of oil leakage

The heat treatment process of the working surface of the wheel body adopts the overall heating and local quenching process. After the working surface is quenched, the wear resistance of the product is improved and the product life is long.

The assembly is assembled by a dust-free assembly line, vacuumed and refueled after the air tightness test, and subjected to a 100% running-in test, and the product quality is stable.

Application

Crawler Bulldozer

Tracked Transporter

Packaging & Shipping

Exhibitions over the years

About US

Fujian Jinjia Machinery Co.,Ltd. is developing from Quanzhou Hongda Machinery Co.,Ltd. The company has dedicated to the manufacturing of crawler undercarriage parts since 1990, which has been more than 30years so far. Now we have established our own casting, forging and machining production centers.

JINJIA Machinery has always been insisting on the operation policy of “Customer first, Quality first” . Our mission is to make customer satisfaction. Just because of this, these years the company has obtained high reputations and solid foundation in the machinery industry. Today our production scales have been constantly expanding, with a wide range of product categories. Our products have been popular in domestic markets as well as the international markets such as Europe, America, South East of Asia, Middle East, etc. We have established good business relationships with famous companies around the world. Welcome to visit our factory for further more technological communications!

FAQ

why should you buy from us not from other suppliers?

The advantages of GM Company: Our state-of-the-art inventory management control system assures that your order is shipped promptly and accurately. GM focus is to provide our customers with the very good quality of parts at a good value.

Can you accept custom orders?

Yes, as long as you reach our minimum order quantity, we can help you customize