KM2503/PC1250 TRACK ROLLER FOR UNDERCARRIAGE PARTS

KM2503/PC1250 TRACK ROLLER FOR UNDERCARRIAGE PARTS

The track roller, which is also called bottom roller or lower roller, is one part of undercarriage parts for crawler heavy equipment such as excavator, bulldozer.

Excavator track roller is made of shell, bronze bushing, collar, seal, lock pin, plug, shaft. It is made by forging, machining, heat treatment, assembly, painting etc.

The quality and working life depends on the quality of raw steels, the hardness of rail surface, the depth of hardness layer, the quality of seal group etc.

TRACK ROLLER DATA PARAMETER FOR PC1250/KM2503

| Material | 50Mn/40MnB |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC50-56 , Depth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 1440 Working Hours |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 25-100/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

Main Features

1.Single and double-edge road wheel suits for caterpillar excavating machine and special machinery ranging 3 to 50 tons.

2.Double conical sealing and lifelong lubrication design enable the road wheel to have longer service life and perfect performance in any circumstances.

3.The shell made by hot forging treatment obtains superior structure of internal materials and fiber.

4.Differential quenching or feed-through quenching heat treatment is effective in crack resistance.

Packaging & Shipping

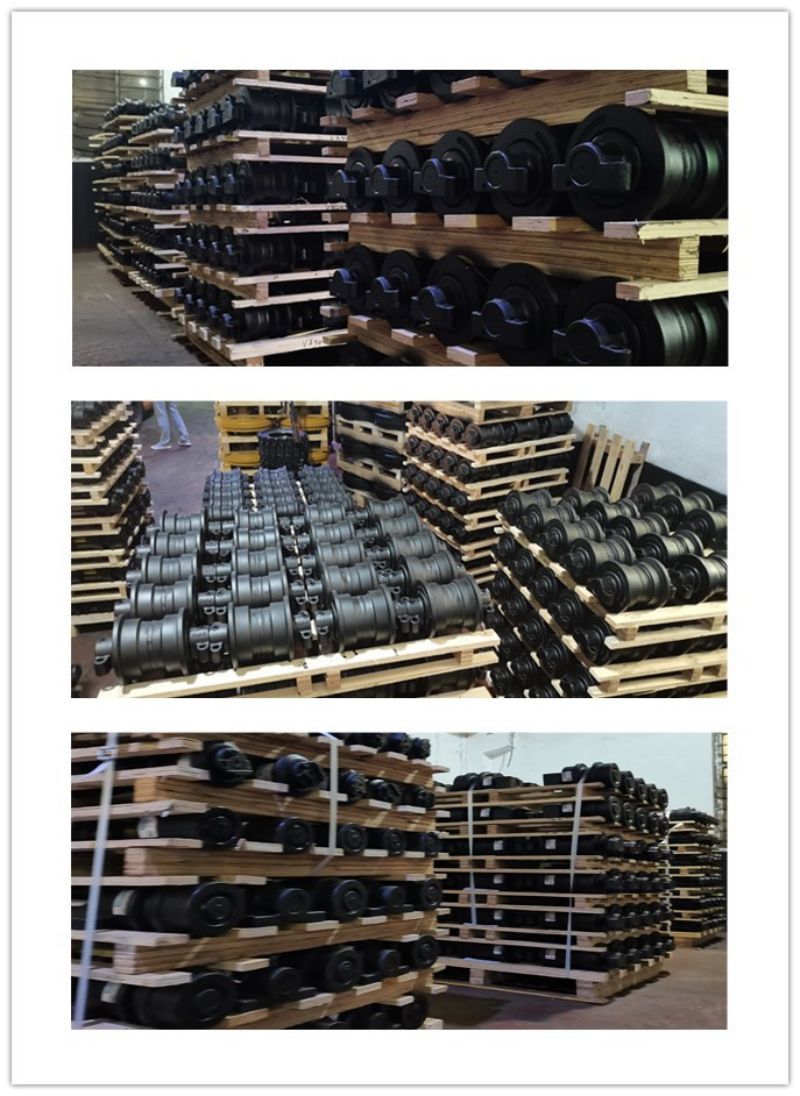

Our Warehouse

FAQ

1. WHAT IS THE DELIVERY TIME AFTER PLACE AN ORDER

Tt is depends on your quantity, if we have the goods in stock, with the normal packing, the delivery time is 4-6 DAYS.on the contrary, 15-30 DAYS after your advanced payment.

2.What about Quality Control?

We have a perfect QC system for the perfect products.A team who will detect the product quality and specifcation piece carefully monitoring every production process until packing is complete,to ensure product safety into container.