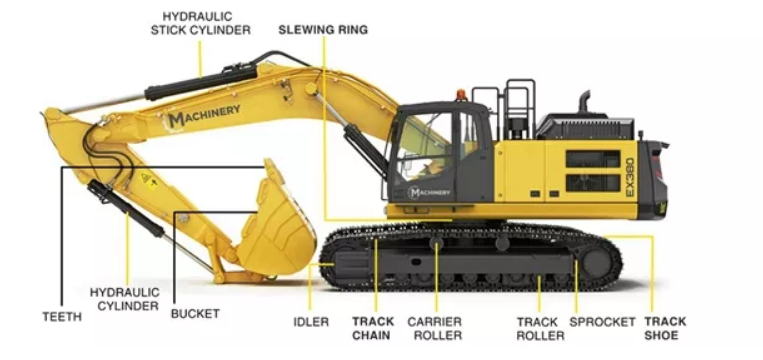

81N8-11010 lower roller track bottom roller for hyundai excavator R305 undercarriage parts

Product Description

The design of double flange rollers is suitable for small excavators and heavy excavators and bulldozers of 0.2-120 tons. Or special versions of rollers for forestry and agricultural applications, both can be used

The double-code seal design extends the service life and is a cost-effective choice.

Our double flange rollers will undergo a series of quenching treatments to ensure that the surface hardness reaches hrc=50. The wheel shells are mainly made of hot forging treatment to obtain excellent internal material fiber flow distribution structure.

Differential quenching has the effect of anti-cracking and prolongs the service life

81N8-11010 carrier Roller :forging material(50MN) Cover material (QT450)Shaft (45#)

Degree of depth :3mm(Shaft1.5-2mm)Hardness:HRC55-60

Roller body: Forging--Turning operation--Quenching--Fine Turing operation --pressure bushing--- welding slag shovel (clean up the body surface)

Shaft forging turning operation drill tapping tapping temper quenching mill right

Handed screw

End cover :forging/casting/steel rod-rough and fine turning operation drill tapping

All parts ready to: assembly-Pressure Test Filling Oil Spray Paint Checking Storage

Our double flange rollers will undergo a series of quenching treatments to ensure that the surface hardness reaches hrc=50. The wheel shells are mainly made of hot forging treatment to obtain excellent internal material fiber flow distribution structure.

Differential quenching has the effect of anti-cracking and prolongs the service life

Top Roller :forging material(50MN) Cover material (QT450)Shaft (45#)

Degree of depth :3mm(Shaft1.5-2mm)Hardness:HRC55-60

Roller body: Forging--Turning operation--Quenching--Fine Turing operation --pressure bushing--- welding slag shovel (clean up the body surface)

Shaft forging turning operation drill tapping tapping temper quenching mill right

Handed screw

End cover :forging/casting/steel rod-rough and fine turning operation drill tapping

All parts ready to: assembly-Pressure Test Filling Oil Spray Paint Checking Storage

Packing and shipping

FAQ

How long is the after-sale time?

Our warranty time about 1440 Working Hours

Can I customize my favorite logo on the product?

It is no problem to customize the logo on the product, as long as you meet our minimum order quantity, you can customize the logo